Thermal Printer Technology Explained: How It Works

The Ingenious Simplicity: Thermal Printer Working Mechanism Explained 💡

Thermal printers are everywhere, though you might not realize it. Every time you get a receipt at the store, print a shipping label for an online order, or check in at an airport for a boarding pass, you’re interacting with the output of a thermal printer. Unlike inkjet or laser printers that rely on ink cartridges or toner, thermal printers use a deceptively simple yet highly efficient process: heat.

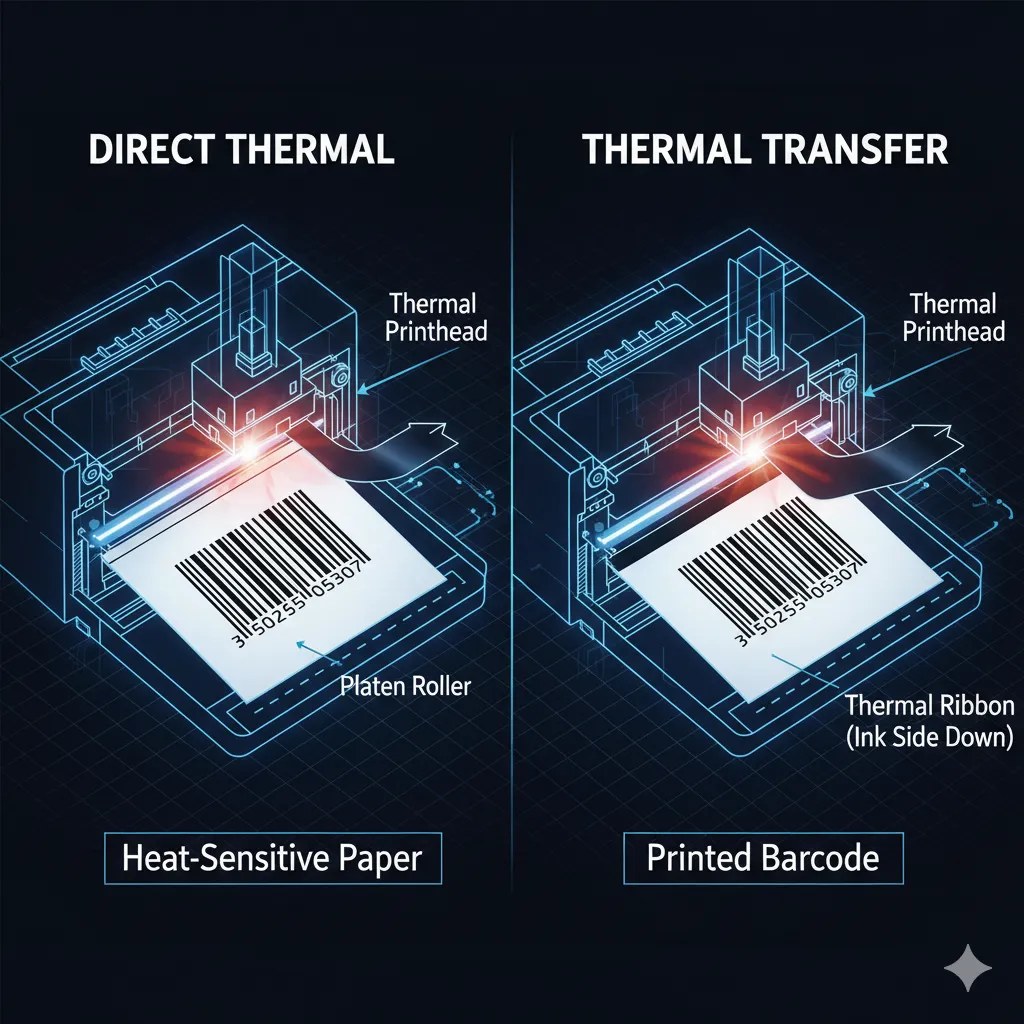

This article dives deep into the thermal printer working mechanism, exploring the two primary types—Direct Thermal and Thermal Transfer—and why this technology is a powerhouse in industries like retail, logistics, and healthcare. Understanding the fundamentals of how a thermal printer works is key to choosing the right one for your specific labeling or receipt needs.

How a Thermal Printer Works: The Core Components

At its heart, every thermal printer contains three main components that work in tandem to create a printed image:

-

Thermal Printhead (The Heater): This is the most crucial part. It’s a stationary strip of tiny heating elements (dots) arranged along the width of the print path. When activated by an electric current, these dots heat up instantaneously to create the necessary energy to form the text or image.

-

Platen Roller (The Feeder): This is a rubber roller that precisely feeds the media (paper or labels) past the printhead. It applies pressure to ensure the printing material is in firm, consistent contact with the heating elements for a clear, sharp print.

-

Spring (The Pressure Regulator): The spring ensures constant, even pressure is maintained between the printhead and the platen roller to prevent slippage and guarantee optimal heat transfer.

The fundamental principle of all thermal printers is using controlled heat from the printhead to create a chemical reaction (in Direct Thermal) or melt a coating (in Thermal Transfer) to form the desired image.

The Two Types of Thermal Printing: Direct vs. Transfer

The term "thermal printer" actually covers two distinct printing technologies, each suited for different applications based on print durability and longevity requirements. Let’s break down the thermal printer working mechanism for each.

1. Direct Thermal Printing: The Ink-Free Solution

Direct Thermal printing is the simpler and more common method, especially for short-term applications.

Mechanism:

-

No Ink, Toner, or Ribbon: This method relies solely on a special heat-sensitive paper (often called thermal paper). This paper is coated with a thermochromic chemical layer, a mixture of a dye and a developer.

-

Heat Activation: As the thermal paper passes directly beneath the thermal printhead, the heating elements are selectively activated. The heat generated causes the thermochromic coating to react, changing its color (usually to black) to create the image or text.

-

Simplicity and Speed: Because there are no ink cartridges or ribbons to manage, these printers are mechanically simpler, highly reliable, and very fast. This makes them a cost-effective choice.

Ideal Applications:

-

Receipts and Point-of-Sale (POS) systems

-

Shipping Labels (short-term use)

-

Tickets (movie, event, or transit)

-

Patient Wristbands

Limitations:

The major drawback of Direct Thermal is the print's sensitivity to environmental factors. The image can fade over time or when exposed to heat, strong light (UV), or certain chemicals. This makes it unsuitable for permanent labeling or archival purposes.

2. Thermal Transfer Printing: The Durable Choice

Thermal Transfer printing is the preferred method when a permanent, durable, and long-lasting print is required.

Mechanism:

-

Involves a Ribbon: Unlike Direct Thermal, this method requires a thermal ribbon, which is a thin film coated with a solid-state wax, resin, or a combination of both (wax-resin ink).

-

Ink Transfer: The printing material (paper, plastic, polyester, etc.) and the thermal ribbon are simultaneously fed past the thermal printhead. The heated elements melt the wax/resin-based ink onto the substrate.

-

Permanent Bond: As the ribbon ink cools almost instantly, it creates a crisp, scratch-resistant, and permanent image that is highly durable. The used portion of the ribbon is then separated and wound onto a take-up spool.

Ideal Applications:

-

Asset Tagging and Inventory Labels

-

Product Identification Labels (requiring long-term durability)

-

Outdoor or Chemical-Exposed Labels

-

Color-Coded Labels (using colored ribbons)

Advantages Over Direct Thermal:

The print quality and image longevity of Thermal Transfer are unmatched in on-demand printing. These prints can withstand harsh conditions, including abrasion, moisture, extreme temperatures, and chemical exposure, making them ideal for manufacturing, logistics, and permanent labeling.

Key Advantages of Thermal Printer Technology

Beyond the unique thermal printer working mechanism, this technology offers significant operational benefits that traditional printers often can't match.

Low Maintenance and High Reliabilit

Thermal printers have fewer moving parts than inkjet or laser printers. In the case of Direct Thermal, the complete absence of ribbons, ink, or toner means almost no chance of print head clogs or running out of consumables mid-print. This translates to less downtime, lower maintenance costs, and high reliability in demanding environments.

Speed and Efficiency

Thermal printers are designed for speed. They have virtually no warm-up time, and the printhead's ability to heat and cool rapidly allows for quick output. This is crucial for high-volume applications like retail checkouts and large-scale shipping operations.

High-Quality Barcodes and Text

The heat-based printing process creates images with excellent edge definition and high contrast. This makes thermal printers perfect for printing highly accurate, scannable barcodes and clear, legible text that meets industry standards for readability.

Choosing the Right Thermal Printer

Selecting the appropriate thermal printing technology depends entirely on your needs. Think about the required print longevity (LSI keyword) and the environment the label will face.

If your prints are temporary (less than six months), like daily receipts, Direct Thermal is the most affordable and simplest choice. If you need permanent asset tags or labels that must survive harsh factory or outdoor conditions, Thermal Transfer is the only way to ensure durable printing and image stability.

Conclusion: Heat is the Future of Labeling

The thermal printer working mechanism is a testament to simple, functional engineering. By leveraging the power of controlled heat, these machines eliminate the mess and complexity of traditional ink-based printing, delivering fast, reliable, and high-quality results. Whether you’re opting for the simplicity of ink-free printing with Direct Thermal or the unmatched durability of Thermal Transfer, thermal technology continues to be the backbone of efficient, modern-day labeling and record-keeping across the globe.

e) External Links

-

Zebra Technologies: What Is the Difference Between Direct Thermal and Thermal Transfer Printing? (Highly authoritative source on printing technology)

-

Energy.gov: Advantages and Disadvantages of Thermal Paper in Receipts (Relevant for environmental and chemical insights on thermal paper, requires searching for a specific page)

-

Wikipedia: Thermal printing (A broad, authoritative overview of the technology and history)